Industry 4.0 in additive manufacturing

Industry 4.0 is a hot topic these days. It is the next step for manufacturing companies. The collection of data and analysing that data to further optimize the production process becomes more and more valuable. At Esma NV we are ready for this next step and we started implementing this on our additive manufacturing plant.

The first step was seeing what data we wanted to collect and what we wanted to achieve with this data. We concluded that we mainly wanted to monitor the quality of the 3D-prints and seeing how we could improve this quality.

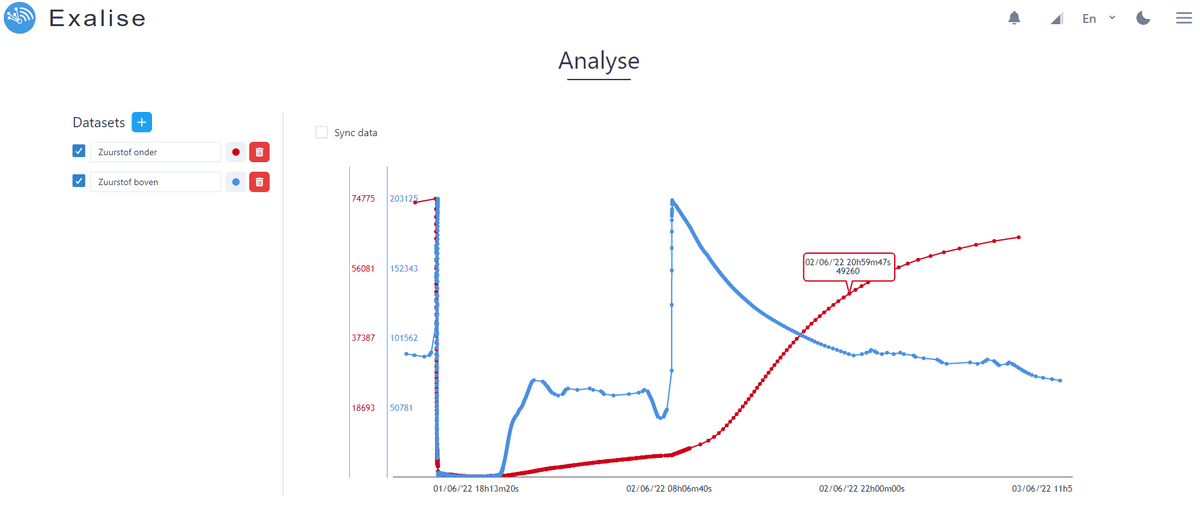

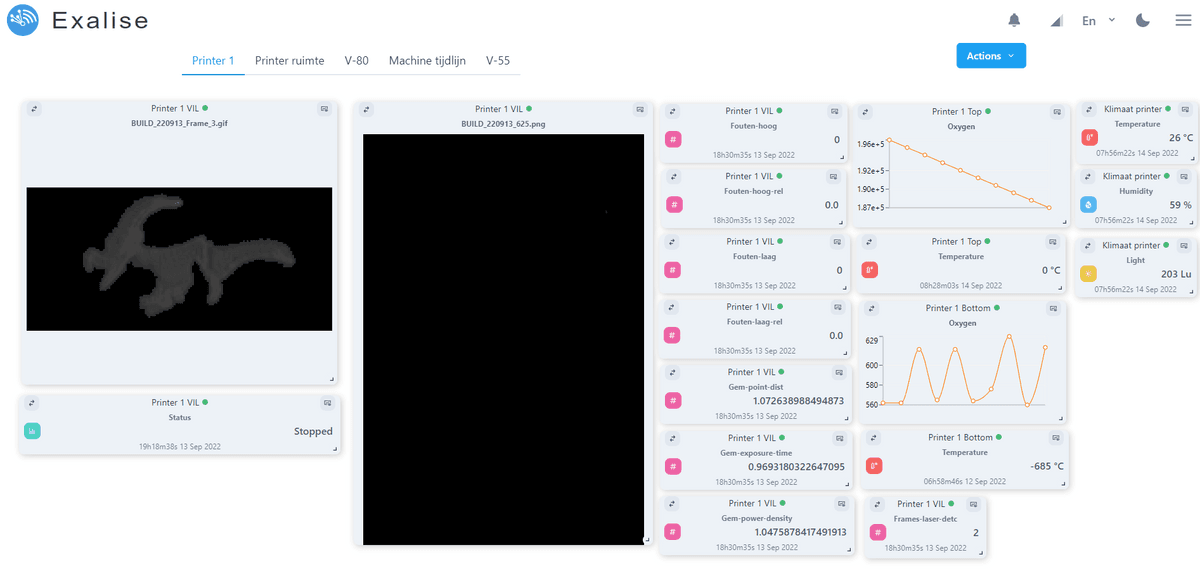

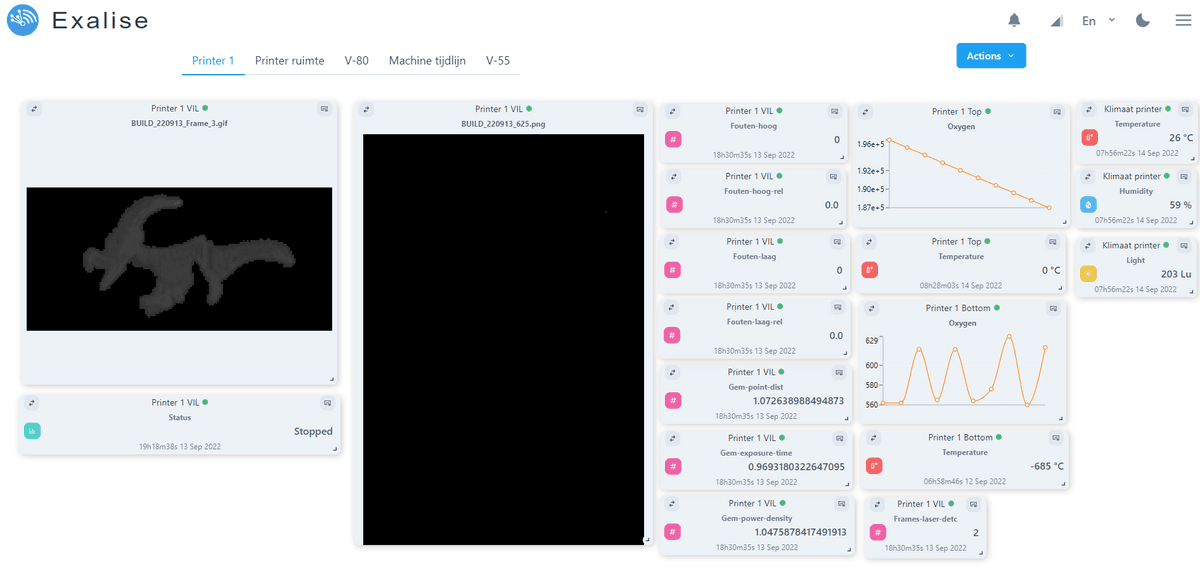

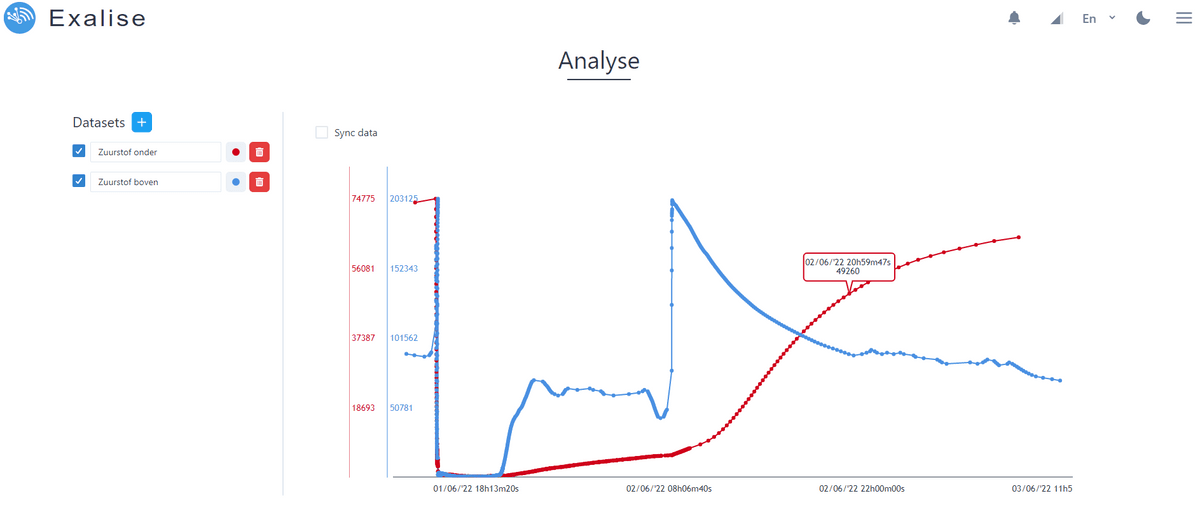

Thereafter we looked at how we could achieve this goal. We started with monitoring the oxygen levels more accurately. We therefore developed our own oxygen sensors and installed them in our 3D-printers. We can monitor these values live and analyse them on our own IOT platform Exalise.

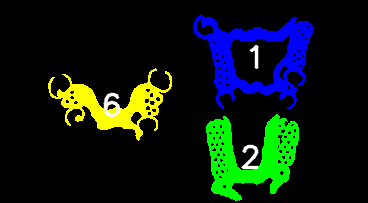

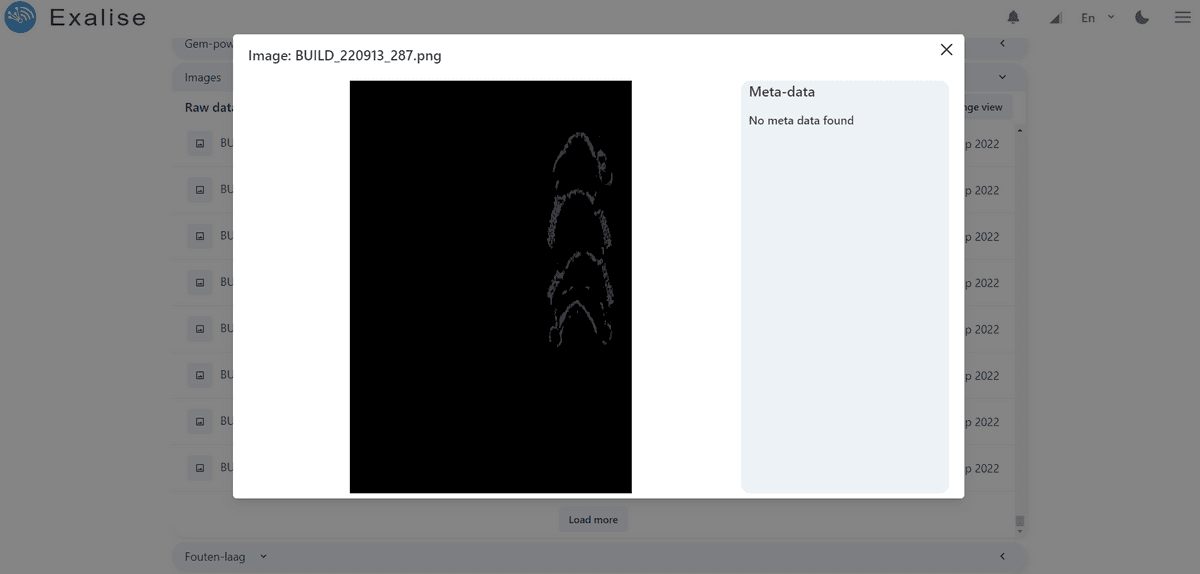

We collaborated with Flanders Make in a VLAIO-project where an advanced camera is placed on our 3D-printers that takes pictures of every laser pulse during the printing process. Thereafter the pictures can get analysed with the use of machine learning to see where there could be a possible weakness or failure in the print. These pictures then get combined into 1 picture of that specific build layer and completely sent to Exalise where we can view them in real-time.

When the printing process is done, all images get collected again. These images will be added on top of each other, the prints get segmented and subsequently a 3D video will be generated. On this 3D video you can see very precise where the weaknesses or failures exist within a print.

All parameters that the camera collects and the oxygen values, will be sent directly to our IOT platform Exalise. All data will be saved safely on a remote cloud server where it can be analysed and monitored live in a customised dashboard. In this way we can monitor and manage everything in real time and stop the machine when too many failures or weaknesses are detected. This saves money and time and it ensures the client of a high-quality product.